So my

recent post on ultrasound systems costs got a lot of attention, more than any article in some time, mostly due I think to a thread in

HackerNews dedicated to it. My original post had some good questions pop up in the comments, and same in the HN thread, along with some replies that clearly had particular assumptions about the medical ultrasound industry. I'll try to address them all in this post.

Now, for those of you who are genuinely interested to get answers, I want to provide them as best I can, and any snark in my post here is not aimed at you. For those who want to sit on the sidelines and snipe, the snark most definitely is. Each of those groups, please read what I write with that in mind.

1) "What about more electronics in the transducer, and GPUs for beamforming?"

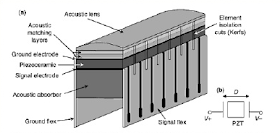

Good question, and transducers are already headed in that direction. After Philips introduced the first real 2D array in around 2003 that was enabled by sub array beamforming electronics in the transducer, there have been advances in that area. However it's important to understand that development of electronics (usually an ASIC) dedicated to a single transducer application is a large investment in money, manpower, and time, then there's the integration of that in the acoustic stack, and making the whole thing work together. It typically takes a substantial team several years to develop that product, and while advances in processes available make this far easier in 2016 than it was in 2003, it's still a lot of work to do. Each of the large companies has a small number of 2D arrays available, but they have to offer substantial benefits over their 1D counterparts as, no surprise, they are a lot more expensive.

Further, make an array 2D instead of 1D and now you've got new data processing challenges - volumes instead of planes, thousands of individual signals instead of ~200. It's all the more computation, so even though the compute available today is increased over the past, the demands are growing too. At some point the computation available economically will exceed the need, but we're not there yet.

But what about the regular 1D arrays? Well, yes there can be more electronics put into there, but remember there are 10 to 20 transducer types per system (cardiac, abdominal, vascular, obstetrics etc each with their own needs), and what makes more sense - a single system with all the common hardware for sampling and beamforming that serves multiple transducers, or all the electronics replicated in each transducer and a simpler system? Economically, right now it makes sense to have all common components in the system, but if electronics get much cheaper/better, then that equation will change and it's something under observation all the time.

If you look

here, you'll see the specs for Verasonics open platform which is a nice hardware package for someone to learn, test, and develop ultrasound on, though commercial premium ultrasound systems are often specced somewhat higher. Sampling is up to 62.5MHz, 14 bit, 256 channels - that's up to 224 Gb/s, or around an entire Blu-ray DVD per second. Thunderbolt will get you to 40 Gbps, so place that all in context and realise that as good as modern electronics are, the demands from high end ultrasound are still beyond it. That will change in time, but again, we're not there yet.

Also note that the voltage that system supplies is up to 190V p-p, which means you can't use the smallest process nodes and get a lot of electronics on each wafer, you have to stick with a process node capable of handling that, so larger electronics and higher cost - and that's not likely to change anytime soon, the fundamental physics limits performance per volt (again, at least for now until better materials come along). The last several years have seen an improvement with the advent of

single crystal piezoelectrics, but right now there's nothing on the horizon giving such a leap again in sight.

Then there's heat. Electronics generate heat, it's just in their nature. A few watts in something as small as a handheld transducer can rise in temperature very quickly, and either burn the patient or the sonographer. There are stringent FDA rules as to how hot a transducer can get, and performance is always limited to make sure that never happens - the transducer basically performs worse than it could in order to be safe. If the electronics for each channel produces 50mW then on a 200 channel probe that's 10W, and will be too much - but if the electronics are 5mW it's 1 Watt total and now gets more interesting. If power consumption could be so low, then it's more of a size/economics argument, not practicality.

Now beamforming. To begin with, for the technically minded among you,

here's a great presentation covering that topic in way more detail than most need. It's from 2005 so a little outdated on some specs, but the basics are still the same. For everyone else, beamforming is taking the raw data and creating an image from it. This involves taking that large flow of data (that 224Gbps), performing a ton of maths operations on it depending on what the imaging mode is, and displaying it, basically a lot of signal processing. The presentation ends with a summary of trends "Analog electronics into probe, digital electronics into software" and that is exactly what is happening, with GPUs now powerful enough to begin to take over from specialised hardware beamformers in some cases, and is likely to increase in speed over the next few years. It will take some time before you see it in the clinic as systems tend to last a decade or more, but it's coming.

So as far as electronics are concerned, there is progress, it is happening, but some of the intense demands of ultrasound mean that the electronics isn't quite there yet, or is only just getting there, and at the same time demands are growing as 2D devices become more prevalent. I expect in 20 years that we'll be looking at a different ecosystem for ultrasound, as cost and performance of electronics shifts workloads between system and transducer.

2) "What about micromachined devices or 3D printing of them?"

Another great question, and something that's been investigated in ultrasound over the last couple of decades. MEMS have been the subject of a lot of funding by both companies and industry for over 20 years for ultrasound. For example, in the early 1990's cMUTs (Capacitive Micromachined Ultrasound Transducers) were hailed as the next great thing in ultrasound, and today in 2016, outside certain specific applications, we're only just starting to see the first commercial devices. That's not due to a lack of effort on the industry's part, all the major players have put major investments into it, but it hasn't quite panned out. There have been issues, many of which have been dealt with, but overall at this time they simply can't outperform piezoelectrics and standard manufacturing in quality and price. There's still work to be done in them, and if they can be made a little better, a bit more consistent, and a bit lower cost, then they will grow in a number of areas, but they need to reach that level of performance that makes them viable. At that point then cost can come down as demand grows, and that virtuous cycle will push more lower cost applications out there. Check out the conference I noted above, there were multiple sessions dedicated to this topic there, and it's got a lot of people working in it. Foundries and semiconductor companies would love to have another high volume application for their fabs, but the right mix of performance, cost, and demand aren't there yet.

pMUTs (piezoelectric Micromachined Ultrasonic Transducers) are being looked at but have some additional difficulties on top of cMUTs. Piezo materials tend to be lead based for good performance, and people don't tend to like lead in their semiconductor fabs, essentially it is often 'not process friendly'. The materials that are, such as ZnO and AlN, are much lower performing so it's limited to applications like FBARs (filters in your phones). There's some promise with scandium doped AlN for better performance, and fabrication methods that allow for better performing piezos, and it's a field to watch but there are still issues. Again, the conference I mention above had a special session on exactly this topic with invited speakers, and was a big draw. Smart experienced people in this field are interested and it will grow.

And 3D printing? It's tough to print some of the active materials and other specialised components of a transducer, but again it's being looked at. GE, among others, is putting

huge company efforts into this, and they and others have given presentations on this effort (again, that conference mentioned - it's almost as if smart people in the industry are thinking about this kind of stuff! :) ) So again, early days, but advanced manufacturing is coming, and it will help with performance, reliability, and prices.

3) "I can buy off the shelf parts for $x, why does the system cost more than $x?"

Quite simply because it takes a lot of effort and manpower to put together a reliable, robust, validated platform upon which people's medical decisions can be based. This would be the case with or without regulation, any product takes this amount of work. If you build something poor quality, you get one sale and no repeat business, and word travels fast - in a competitive world like ultrasound, you lose your name quickly and you're done. Each transducer has to support multiple imaging modes - b-mode, harmonic, doppler etc - and each takes time to program and validate. Then you have to support it, and keep your customer happy, all while keeping your staff paid well enough to not jump ship to the latest social app, and be building the next generation of improved systems. Basically, standard business issues and costs that face any long term enterprise. Oh, and profit, that helps to keep companies going, products being made, and new advances worth funding.

In summary - this stuff is coming, but it's not as easy as you might think, and it's not a microphone on a smartphone that can fail or be disposed of in a couple of years.

Want to be a part of it and learn more? Please do, our industry is always looking for talented people to help make ultrasound better. Attend conferences, take it as a postgraduate course of study, join an ultrasound company or start one. Want to really get involved? Message me, I'm well connected in the industry and will put you in touch with anyone I can to help.

Now the more business side of things - and again, remember the snark is not aimed at those with genuine questions and interest:

4) "You didn't give detailed costs of all the components to prove it's priced low"

First of all, doing so would lead to an exceptionally bland article reading more like a parts list, where I wanted to give more of an idea of what is involved in building a system and that it's not as simple as you would think. The original piece in Medium was based on a number of statements about the simplicity of ultrasound and I wanted to make the point it's a difficult, multi-disciplinary task with a lot of trade-offs. To someone versed in the field, it basically read as "I can build a soapbox derby car for $100, if I stick a motor in it I have a car! Why do these car companies charge $50,000 for one of their cars!?!" (I exaggerate, but not by much.)

Secondly, I actually have to be careful about stating specific numbers, both in pricing and capabilities. I've done work for a number of ultrasound manufacturers, and I have to be sure I do not release any proprietary information, so I tend to err on the side of caution here and make sure to be certain that everything I talk about is already public domain. I'm happy when people not encumbered by such restrictions pitch in.

Lastly, the market is highly competitive, and the fact that it's not priced lower is indicative that something is both worth paying for and priced correctly. If you think the market isn't competitive, I'm not sure what I can say to convince you otherwise, but this next part will try.

5) "There's a conspiracy among manufacturers to keep prices high"

I have to say, hearing this surprised me. I've been in the industry for over 20 years and never once even seen the hint that this is happening in ultrasound, with massive evidence pointing instead to intense competition. It's a multi-billion dollar market (

est ~$6 billion), with several large international players (this link

here has some of the larger, this link

here shows dozens of smaller ones,

this market research report mentions 25 companies), and regulated in a way that it's hammered into everyone to be sure there's no price fixing, collusion/cartels, or other anti-competitive behaviour. Companies have moved up and down the rankings significantly over the last decades, each is always looking (ethically and legally) for a technical or price advantage over its competitors. Medical ultrasound is also a heavily regulated market, and multiple countries (esp the EU and US) will come down hard on a company in this space participating in anti-competitive behaviour.

In every company I've worked I've seen strong pressure to simultaneously raise quality and reliability while lowering costs, and if you look at systems on the market today compared to the past then there have been major improvements at the top end where prices have remained fairly constant, and this has had the knock on effect of allowing the introduction of lower cost and capability systems further down the chain that exceed the capability of yesterday's premium systems.

If someone could start a company that produced ultrasound systems at quality and consistency, with volume, but lower cost, I guarantee you they would be bought by one of the bigger players to incorporate and take advantage of that technology. So if you feel there is a conspiracy, and that ultrasound systems are in fact easy to make, then feel free to start that company yourself and take advantage of the free money everyone else is passing up. Or, even better, I'll help you - quite seriously, email me, tell me what we're doing wrong, and I'll either find a way to hire you, get you a job in the industry, or let's start that company and make our millions. Seriously, mail me and let's do that, or if you're certain there's a conspiracy then I can provide you with the contact details for various regulatory agencies in various countries who would love to see your evidence they can prosecute with.

To make it clear - few industries actually operate in a market that has such intense competition, among many large players, each trying to provide the customer with the best price and quality mix to make the sales, and leapfrog their competition. This is not an "

Intel own 99% of the server market and have little competition to drive prices down", it's more like competition in the car industry where there are many players competing.

6) "Engineers don't know what they are doing and are passing up really obvious and simple things that will make the products much faster, better, and cheaper."

This industry is made up of thousands of dedicated engineers, researchers, and support staff who are smart, highly educated, very experienced, and highly capable. If they wanted to, many could move to doing things like apps, social media, or whatever the fad of the moment is and make more money with less stress. But they don't, because they love what they do, they live to make technology better, or faster, or cheaper, and because they know that the work they do in ultrasound imaging helps people and makes a difference. That they'd willingly pass up technology advances and better methods just goes against character, and given the attitude of these people and the competition in the industry, if management decided for them not to pursue such benefits, they'd leave for another company or start their own.

There are multiple professional organisations that are dedicated solely to ultrasound, and heavily to the medical side of that.

IEEE UFFC is one such organisation, I'm heavily involved in it, and there are several others. The IEEE is non-profit, solely concentrating on technology, and does not support any single company or commercial interest. They produce peer reviewed journals on state of the art in transducers, materials, electronics, systems, and imaging, and every year have a conference where a couple of thousand people attend and present, discuss, and learn about the best practices and technologies. This year I watched presentations on 3D printing of transducers, new materials, rapid imaging techniques made possible by GPUs, micromachined devices, and advanced electronics for transducers (

This page has a list of talks and the abstracts if you want to see what was covered). These are things that companies are spending plenty of resources researching, universities have students doing Ph.D's on them, and over time

will make their way into products as the technology matures and becomes reliable and cost effective.

If you feel that, without experience in this industry, you are already superior to those who have worked in it for years, then send me your resume. I know companies that will hire someone so skilled to give them an advantage over the competition, or will hire you as a consultant. Or I'll help you get an abstract accepted to the IEEE UFFC conference so you can get your knowledge out there. I'll work with you to get a grant from the NIH or NSF to develop your technology and patent it, or just put it out there online for the world to see - do it for the benefit of the world. Or admit it's armchair quarterbacking. Plenty of options.

Summary - The field is made up of smart, dedicated, and committed people who strive to make quality, well priced products at a variety of price points that make technical and economic sense. Please don't make statements that are predicated on them being stupid, ignorant, or greedy without some evidence to back it up.

7) "All the costs are regulatory, without the FDA we'd have safe machines at a fraction of the cost!"

This is going to be tough to disprove without giving internal costs from various companies, and I can't, and won't do that. I know that regulatory is certainly an aspect of it, but doing a headcount it's not in the top few for costs. There are engineering tests and documentation burdens, but they're really not far beyond what any engineering team concerned with good record keeping and producing a safe device would do. And importantly, having clear regulations allows all participants to compete on a level playing field, knowing that everyone is playing by the same rules.

Yes, you can buy a veterinary, unregulated ultrasound machine from AliBaba. Good luck with it giving you a quality or even useful image, not injuring you, being reliable, or getting any support on it. Or getting it to do a fraction of the things a premium ultrasound system will.

Once again, there's a reason that ultrasound is the most widely used medical imaging modality, and is incredibly safe, and part of that is the FDA and similar regulation.

8) "Are you stupid you can't make a transducer without sharp edges!"

This is to reply to one specific comment. Ultrasound is unlike MR and CT in that it is both operator and patient dependent - each image can be different and some skill is required. The acoustic window in which clinically useful images can be gained sometimes involves placing the transducer in a location, and applying sufficient force, that it can be uncomfortable for the patient. If the patient starts to move because it's uncomfortable, it makes getting a good image harder. Some transducers have a tradeoff of minimised size for access to certain locations, but maximised acoustic area for good image, which can lead to corners that are not very smoothly rounded, and while not 'sharp' as in 'cuts the patient', might lead to more discomfort than necessary if not designed correctly. Oh, and yes building a 200 wire cable with minimal crosstalk is easy, doing it and making it flexible so a sonographer can use it (like I said in the original post), and at a reasonable cost isn't. Congratulations to the person that asked that question and showed their genius in how dumb we ultrasound people are - you actually managed to annoy me with those comments! You, in particular, are an author I aimed the "Since you're so smart, why don't you clean up in our industry of charlatans and idiots?" snark at.

9) "Phones are cheap and have a ton of technology in them, why aren't you that cheap?"

>Several hundred million phones are sold every year, probably 4 orders of magnitude more than ultrasound systems. On average they last about 18 months to 2 years, compared to a decade or more for an ultrasound system. No-one's life depends on them. One of the simplest things here is there just isn't the economy of scale for ultrasound to hit those price points. Perhaps it's a chicken-and-egg thing, that the "killer app" for ultrasound isn't here because it's too expensive, but if the demand is there then the tech will come. Got that application? As some have noted, there are rumours that's what Butterfly Labs are working on, but despite being well connected in the industry, I've heard nothing on what they are really doing after several years of effort. I hope they produce something astounding, but until then, no smartphone market economies of scale for ultrasound.

OK, I'm done for now and leave you with this, once again - If you can make a difference in this industry in price, performance, reliability, or application then get in touch, there are companies and universities that want good people to work on this. Don't armchair quarterback or cite imaginary conspiracies, get involved.

Merry Christmas everyone.